Reacting to the new industrial challenges, the Savoy International group sought to bring together the tomorrow’s know-how in a technological center. The latter brings together the Robotics activities, plastic and metal additive manufacturing as well as the design and production of plastic injection molds. Mastering these technologies reduces the time-to-market for the development and industrialization of new products.

Presentation

Presentation

Reacting to the new industrial challenges, the Savoy International group sought to bring together the tomorrow’s know-how in a technological center. The latter brings together the Robotics activities, plastic and metal additive manufacturing as well as the design and production of plastic injection molds. Mastering these technologies reduces the time-to-market for the development and industrialization of new products.

SAVOY FUSION LASER

METAL & PLASTIC 3D PRINTING

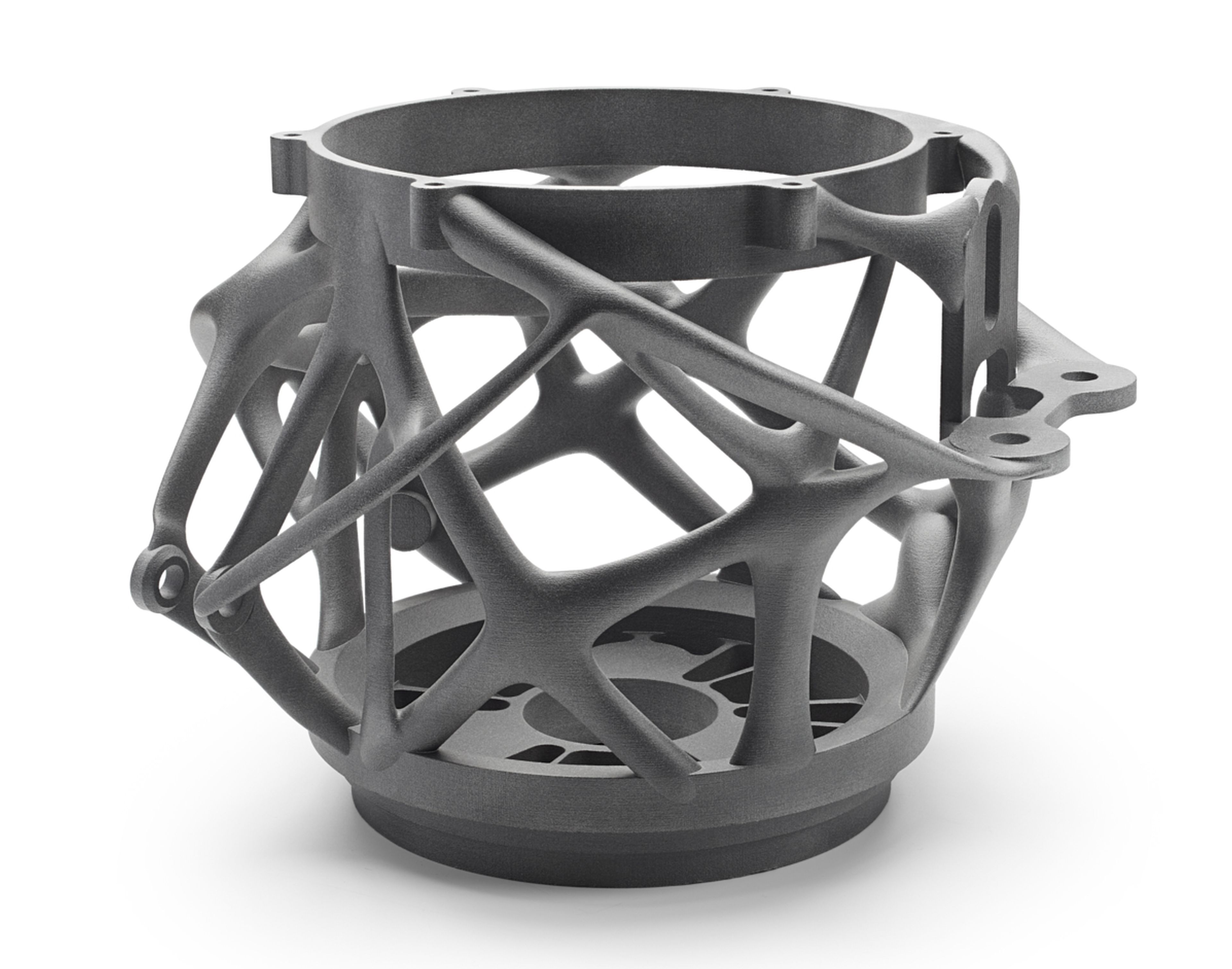

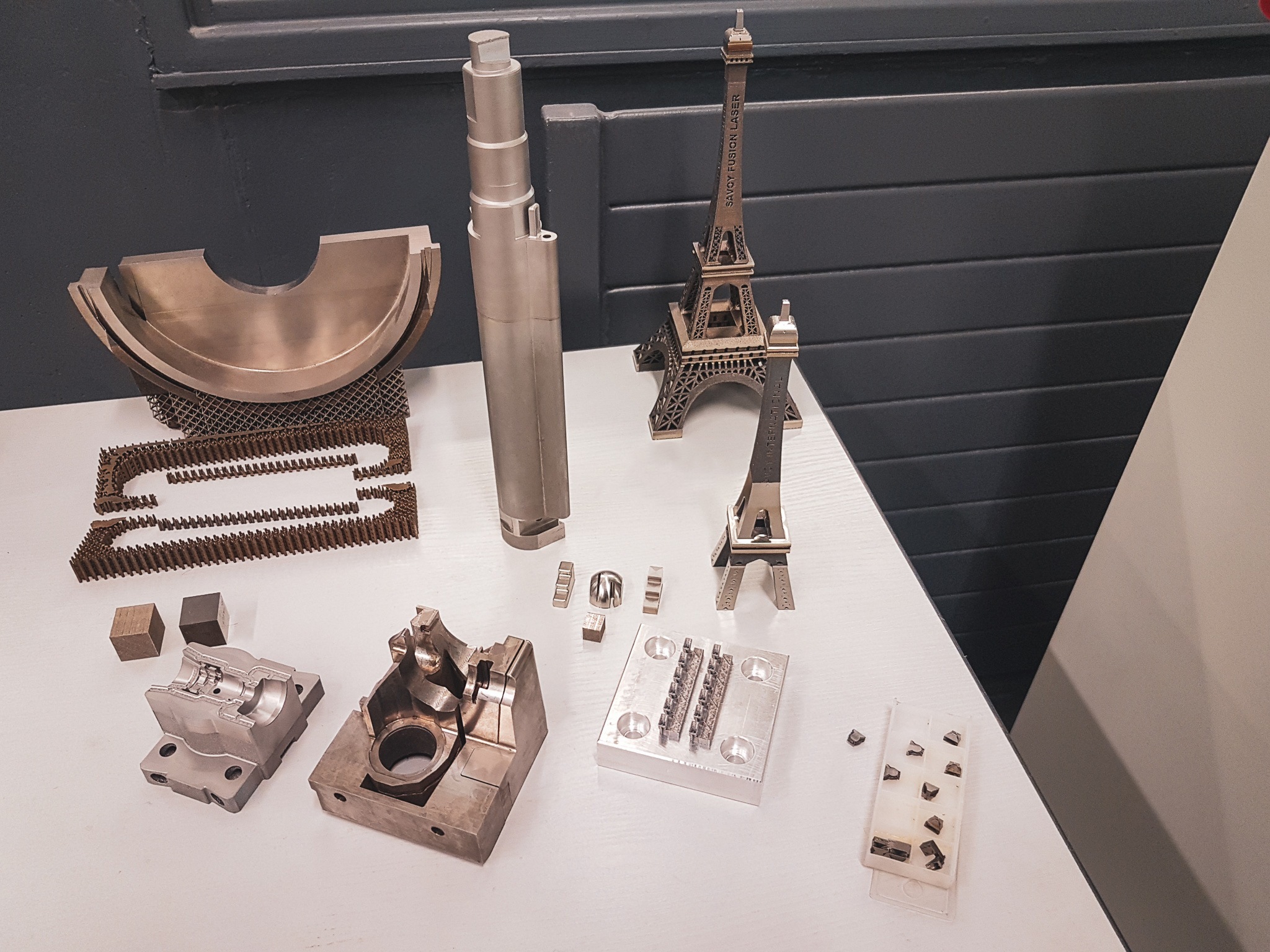

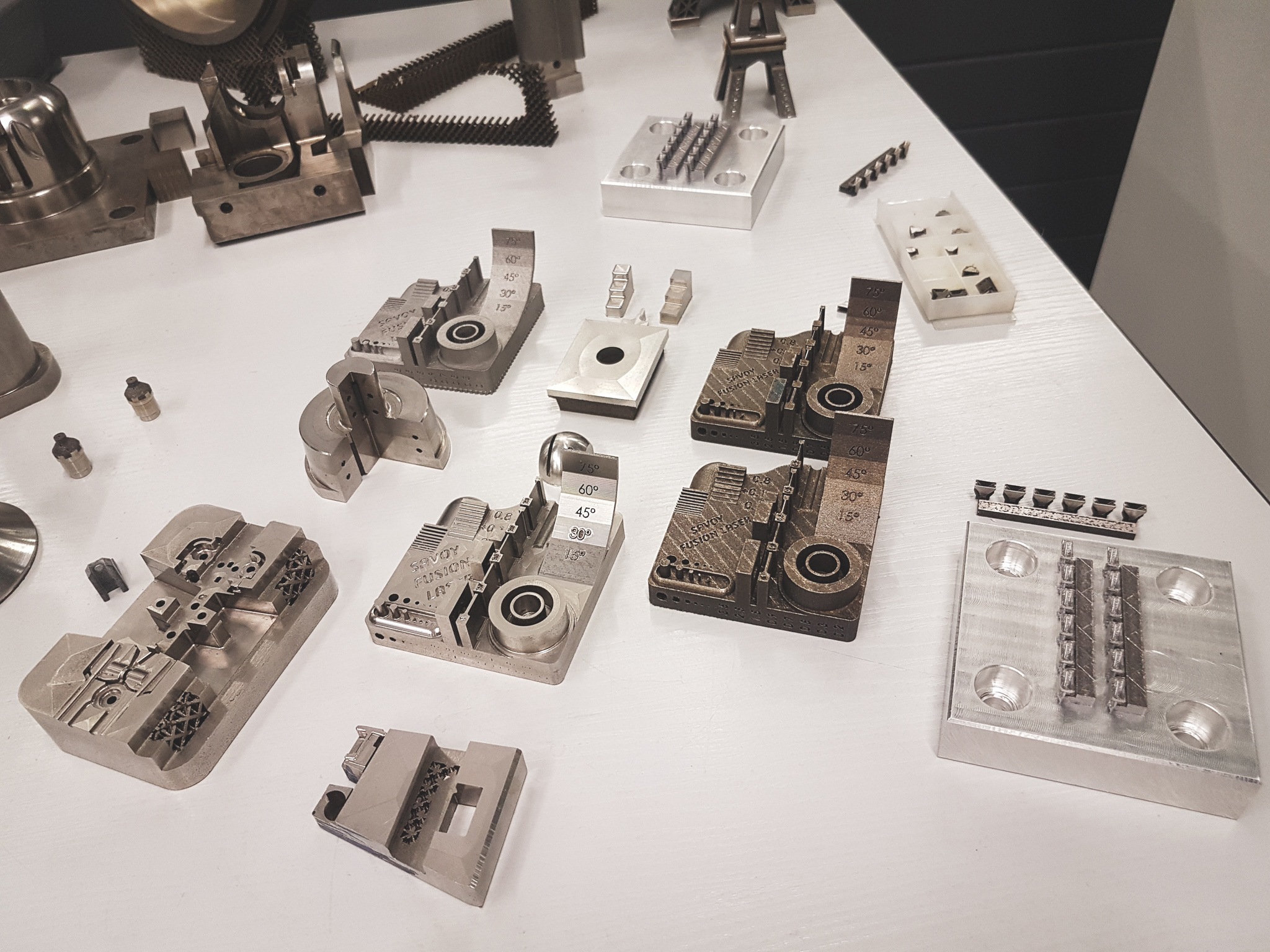

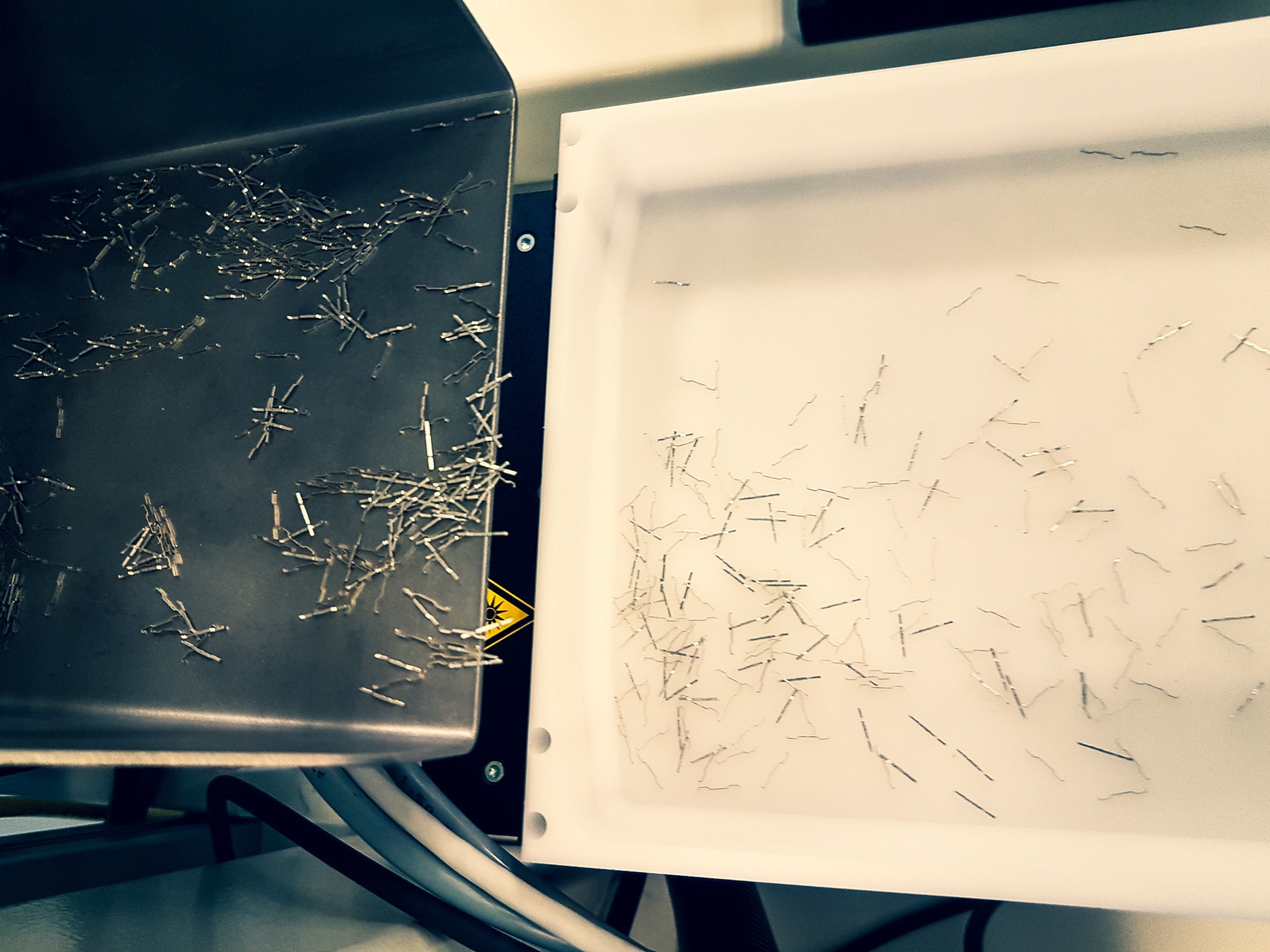

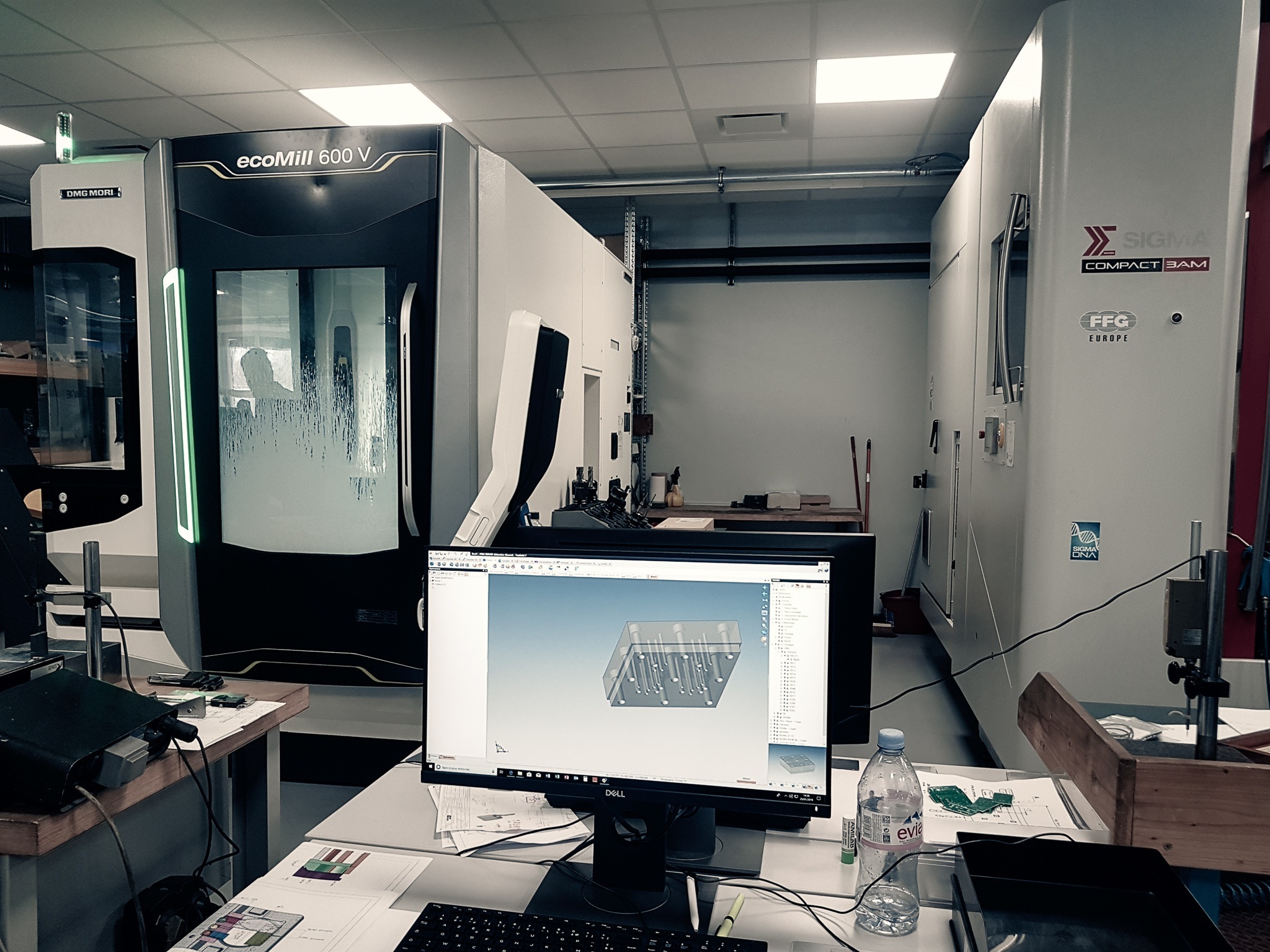

Savoy Fusion Laser is the additive manufacturing division of the Savoy International group. Metal 3D printing has been achieved through two Hybrid Metal 3D laser printers from Matsuura (Lumex 25 & Lumex 60), using the Selective Laser Sintering process (SLS) and equipped with a high speed milling unit, allowing the machining of the part being printed. They can fused materials like Aluminum, Maraging steel (tool cavities) and stainless steel.

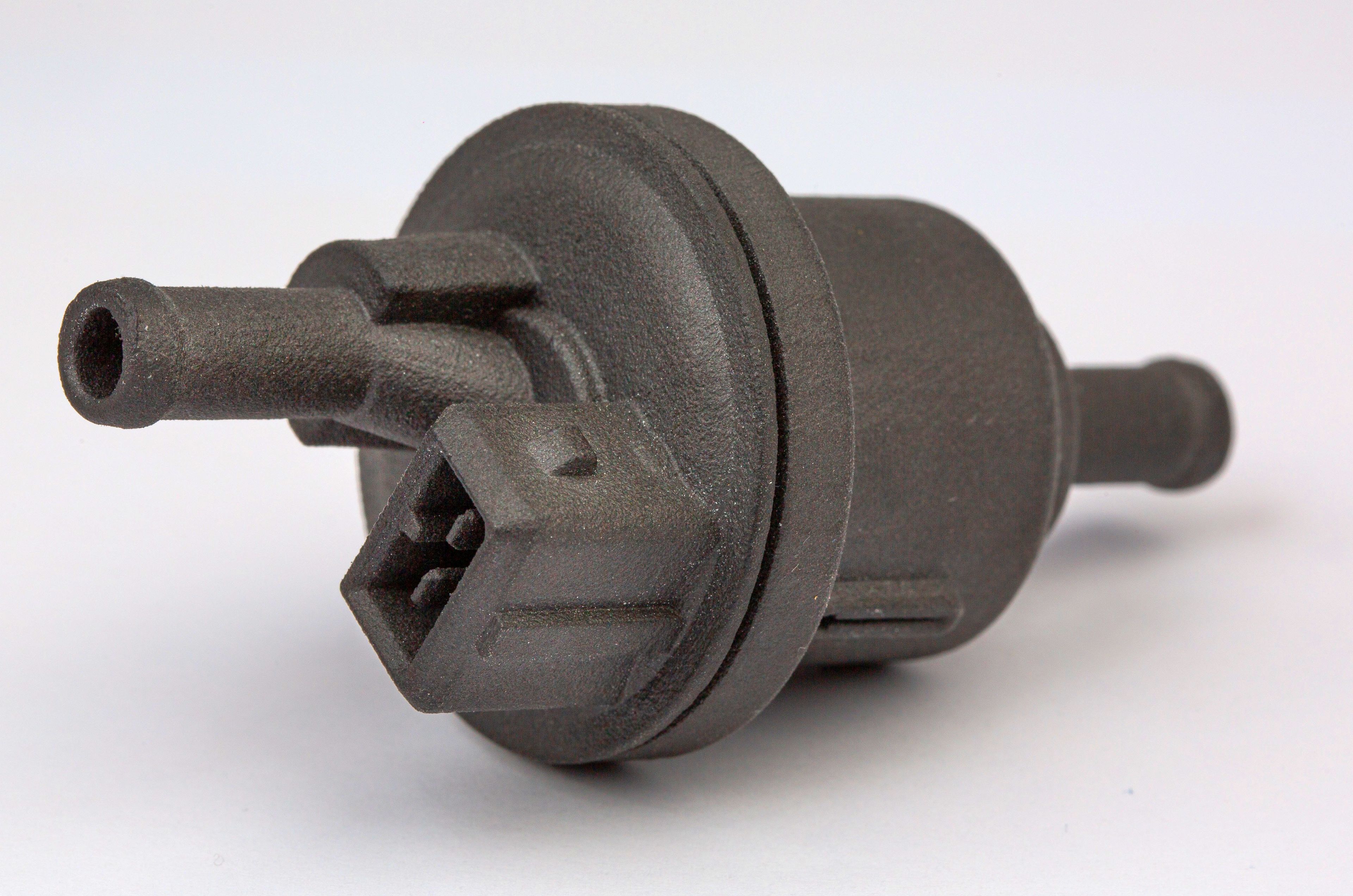

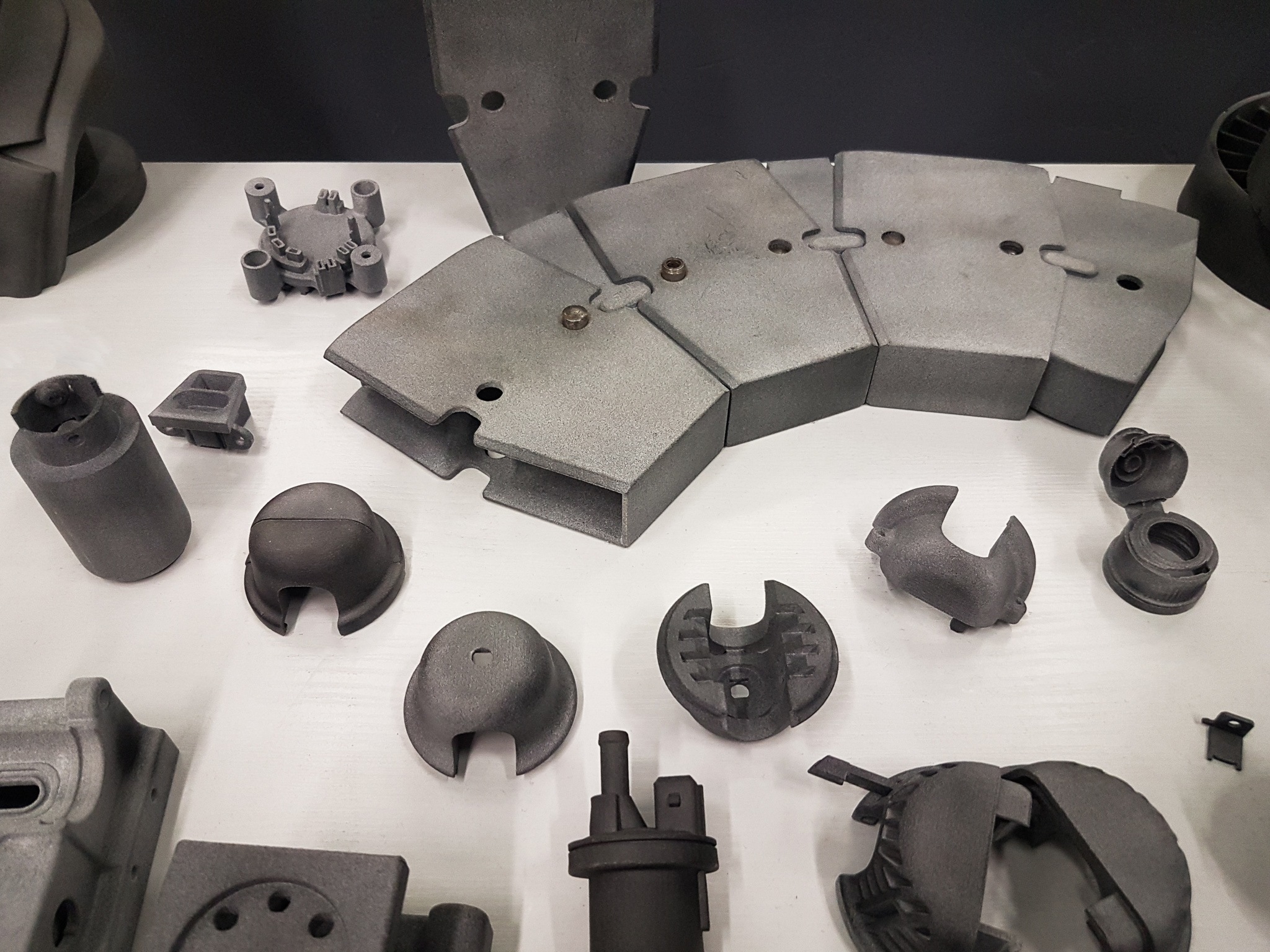

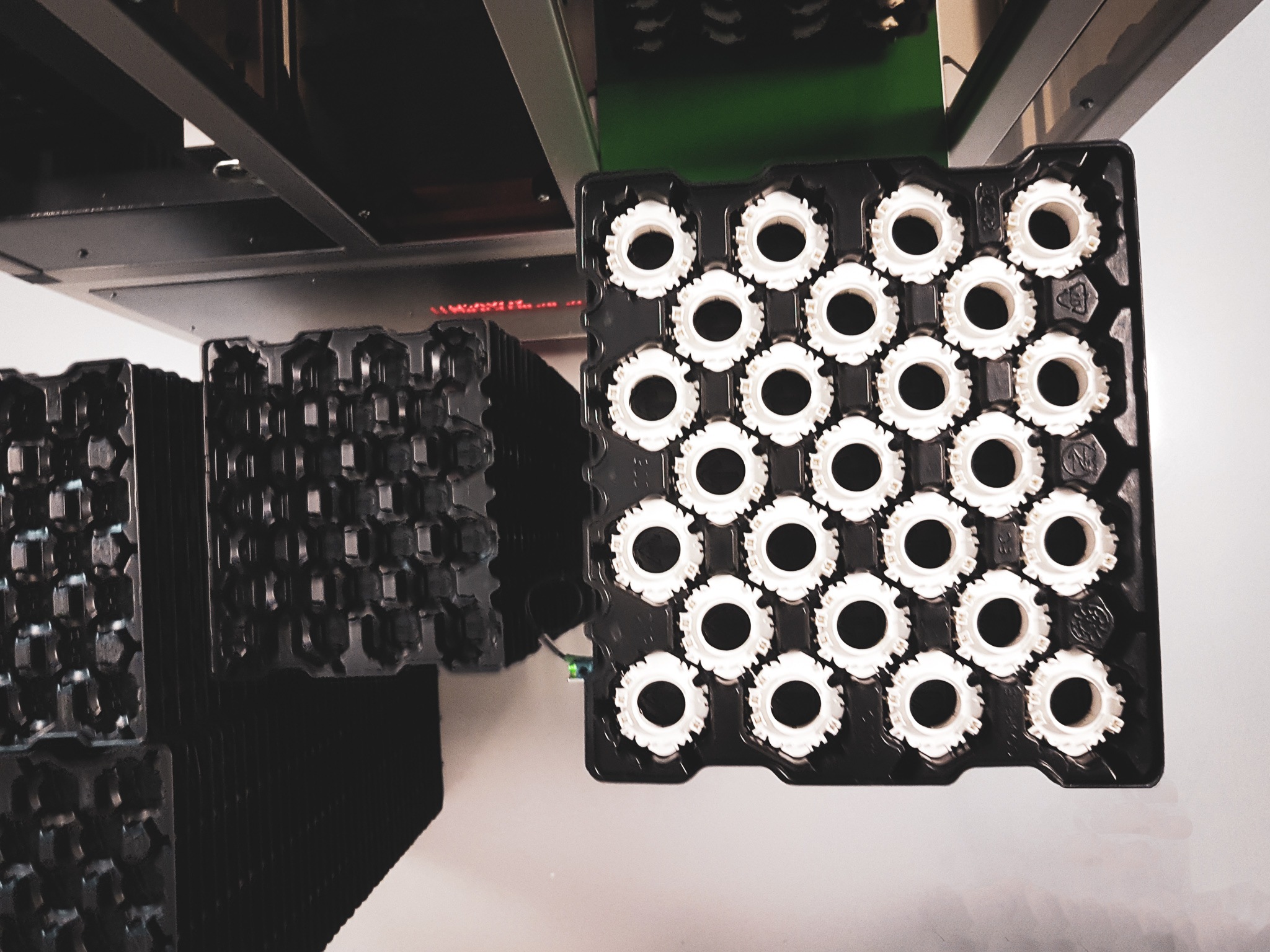

Plastic 3D printing is performed with HP’s Multi Jet Fusion (MJF) technology. The parts are printed in polyamide 12.

SAVOY FUSION LASER

METAL & PLASTIC 3D PRINTING

Savoy Fusion Laser is the additive manufacturing division of the Savoy International group. Metal 3D printing has been achieved through two Hybrid Metal 3D laser printers from Matsuura (Lumex 25 & Lumex 60), using the Selective Laser Sintering process (SLS) and equipped with a high speed milling unit, allowing the machining of the part being printed. They can fused materials like Aluminum, Maraging steel (tool cavities) and stainless steel.

Plastic 3D printing is performed with HP’s Multi Jet Fusion (MJF) technology. The parts are printed in polyamide 12.

Services

3D printing and machining of metal parts

3D printing of high-tech plastic parts

Prototype industrial design

Production of assembly machine elements (inlet and discharge chutes, racks, sensor holder)

Commercial contact

Daniel Rey

Email : drey@savoy-moulage.com

Tel : +33 6 78 29 54 66

Services

3D printing and machining of metal parts

3D printing of high-tech plastic parts

Prototype industrial design

Production of assembly machine elements (inlet and discharge chutes, racks, sensor holder)

Commercial contact

Florent Manouvel

Email : fmanouvel@savoy-moulage.com

Phone : +33 6 13 94 11 57

Daniel Rey

Email : daniel@savoy-moulage.fr

Tel : +33 6 78 29 54 66

METAL & PLASTIC 3D PRINTING

A question about a product or service? Arrange a meeting ? Need a quote?

Our support team look forward to assisting you

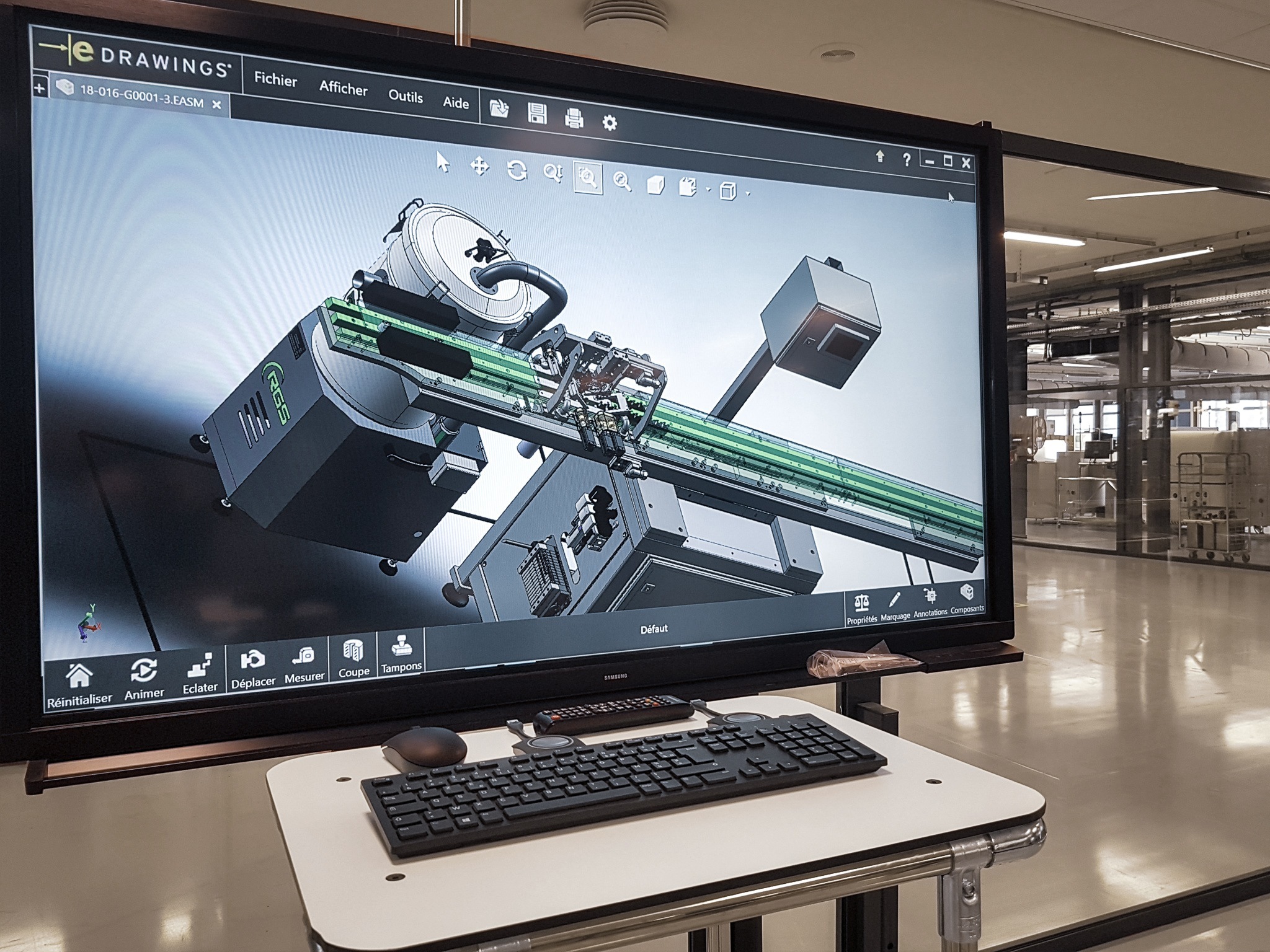

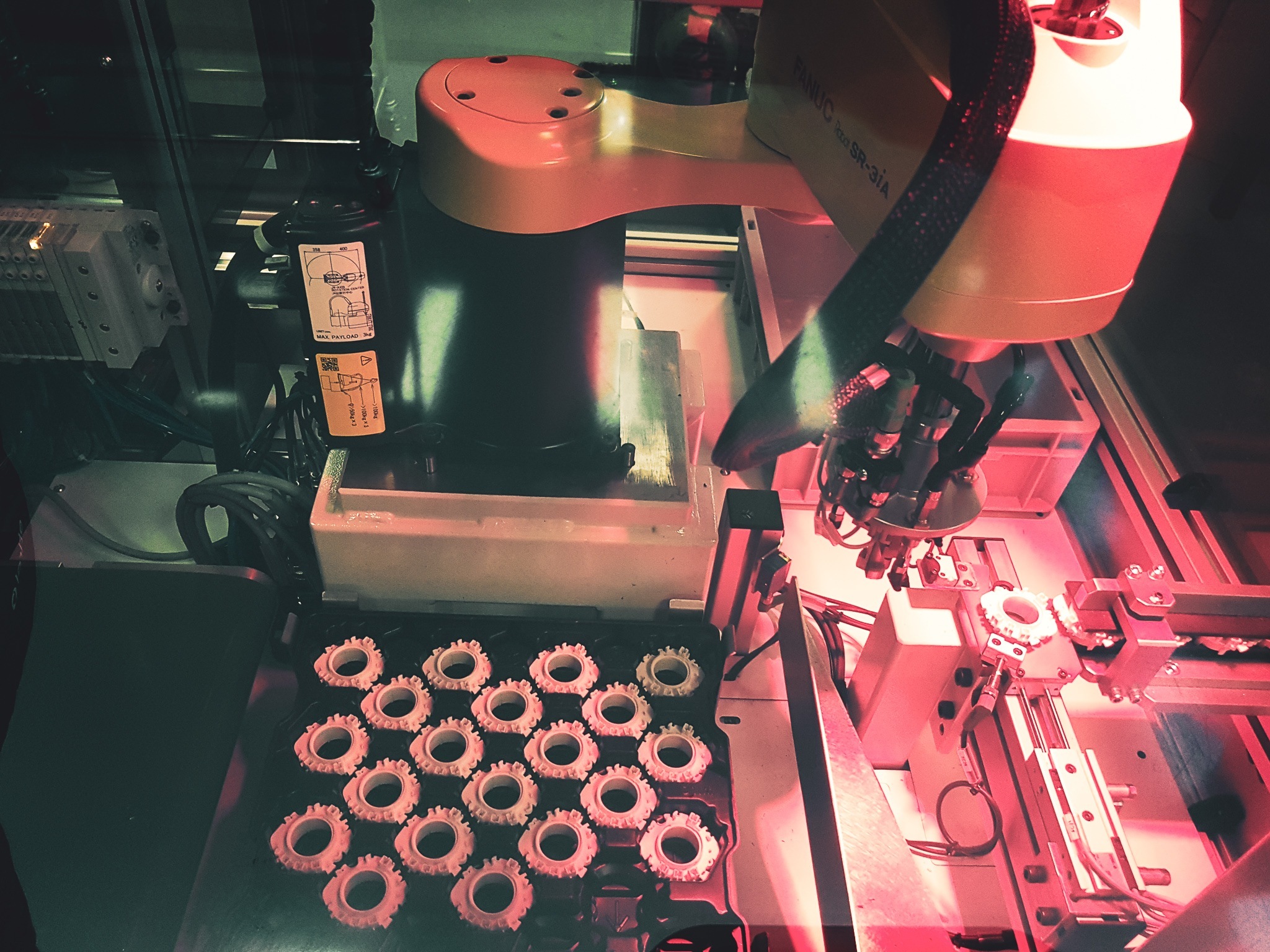

SAVOY INGENIERIE ROBOTIQUE

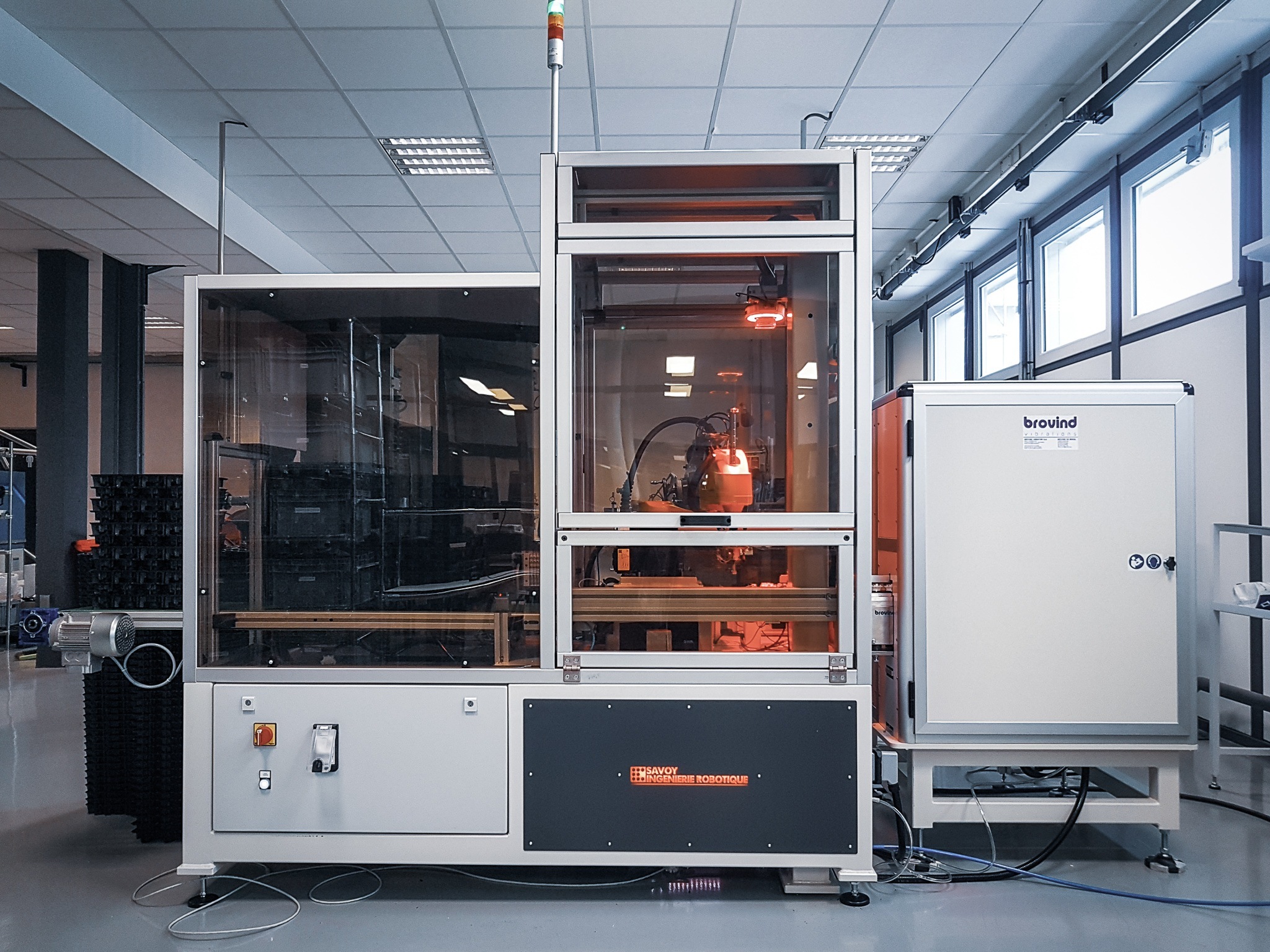

In order to meet new development and adaptation requirements, Savoy Ingenierie Robotique integrates “co-worker” robots assisted by racking systems. The company also develops Automotive Intelligent Vehicle (AIV) for use in the production sites. Savoy Ingenierie Robotique is an essential support for the implementation of a Lean Manufacturing strategy in the Savoy International group.

SAVOY INGENIERIE ROBOTIQUE

In order to meet new development and adaptation requirements, Savoy Ingenierie Robotique integrates “co-worker” robots assisted by racking systems. The company also develops Automotive Intelligent Vehicle (AIV) for use in the production sites. Savoy Ingenierie Robotique is an essential support for the implementation of a Lean Manufacturing strategy in the Savoy International group.

Commercial contact

Olivier Jean

Directeur SIR

Email : ojean@savoy-ingenierie-robotique.com

Phone : +33 6 70 08 33 25

Commercial contact

Olivier Jean

Directeur SIR

Email : ojean@savoy-ingenierie-robotique.com

Phone : +33 6 70 08 33 25

SAVOY INGENIERIE ROBOTIQUE

A question about a product or service? Arrange a meeting ? Need a quote?

Our support team look forward to assisting you

SEROP

Multi-cavity plastic injection molds

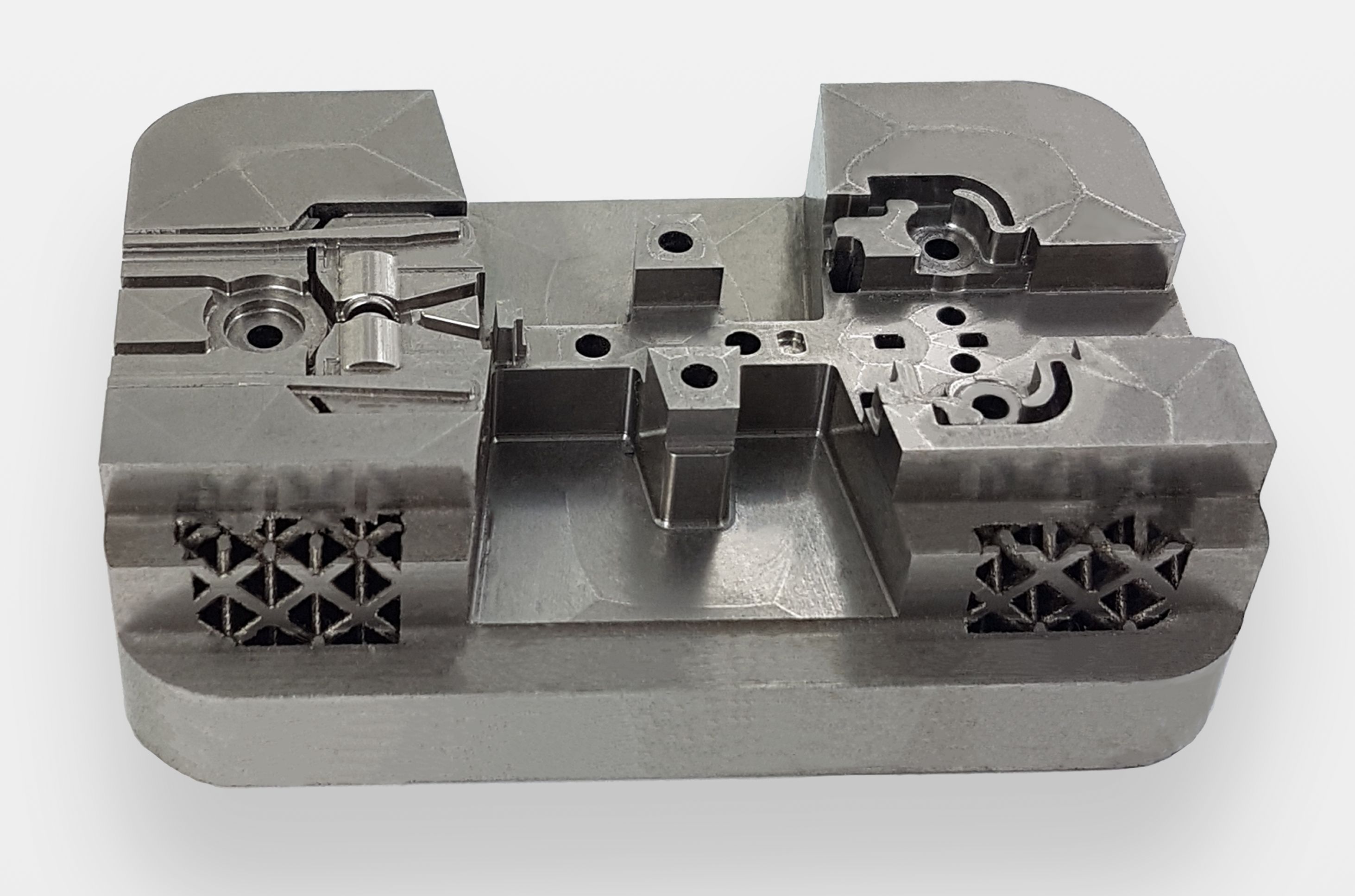

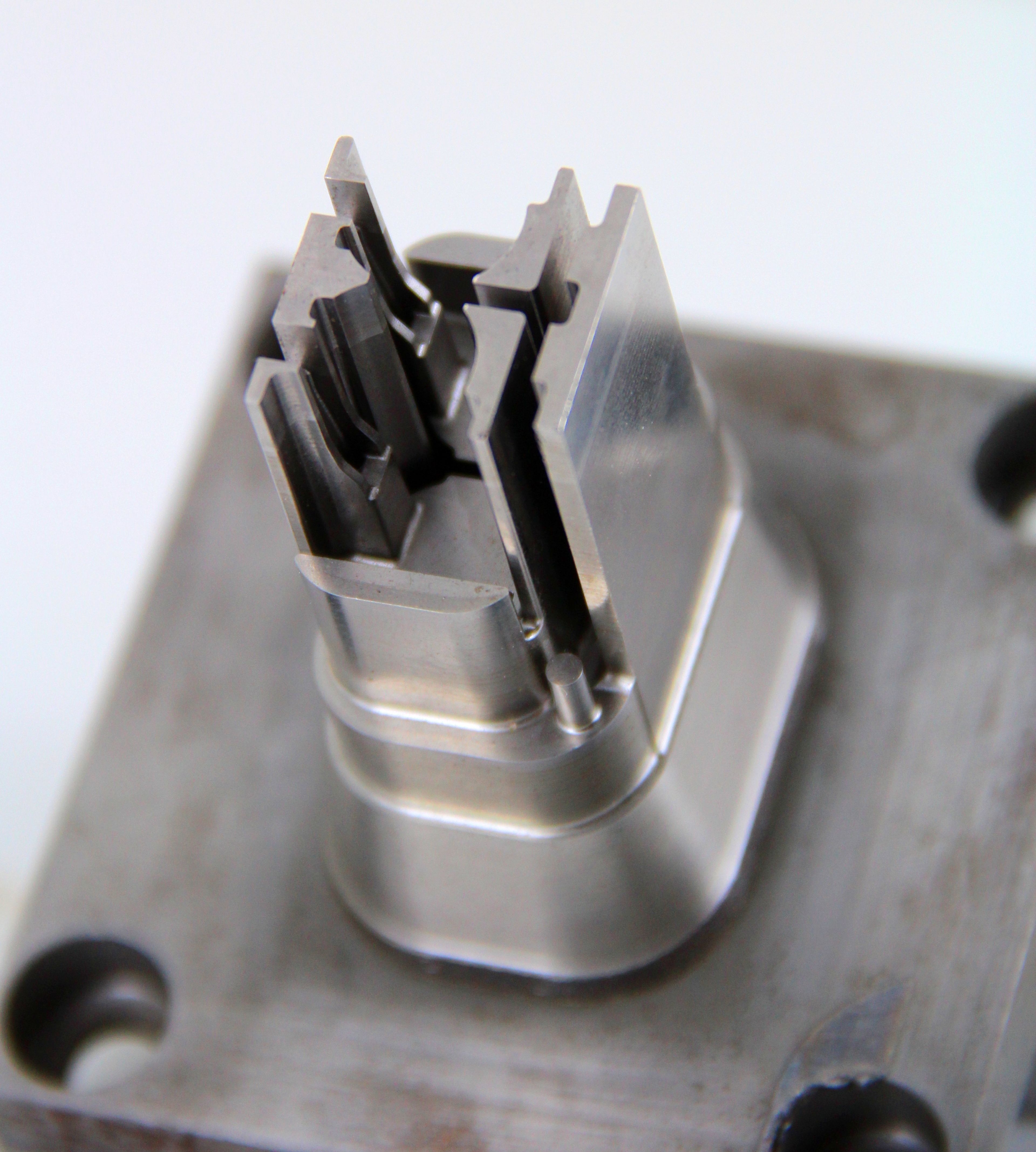

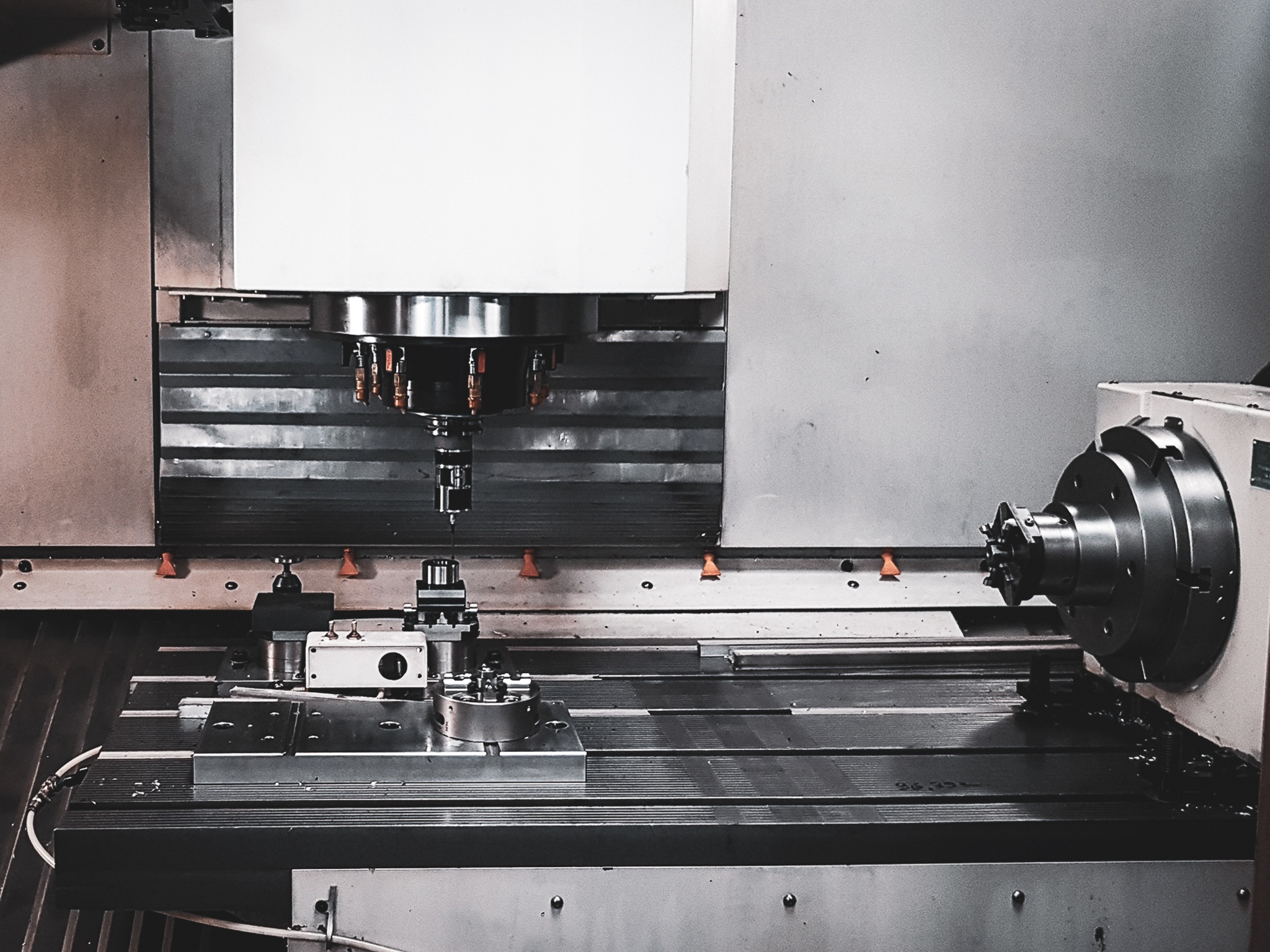

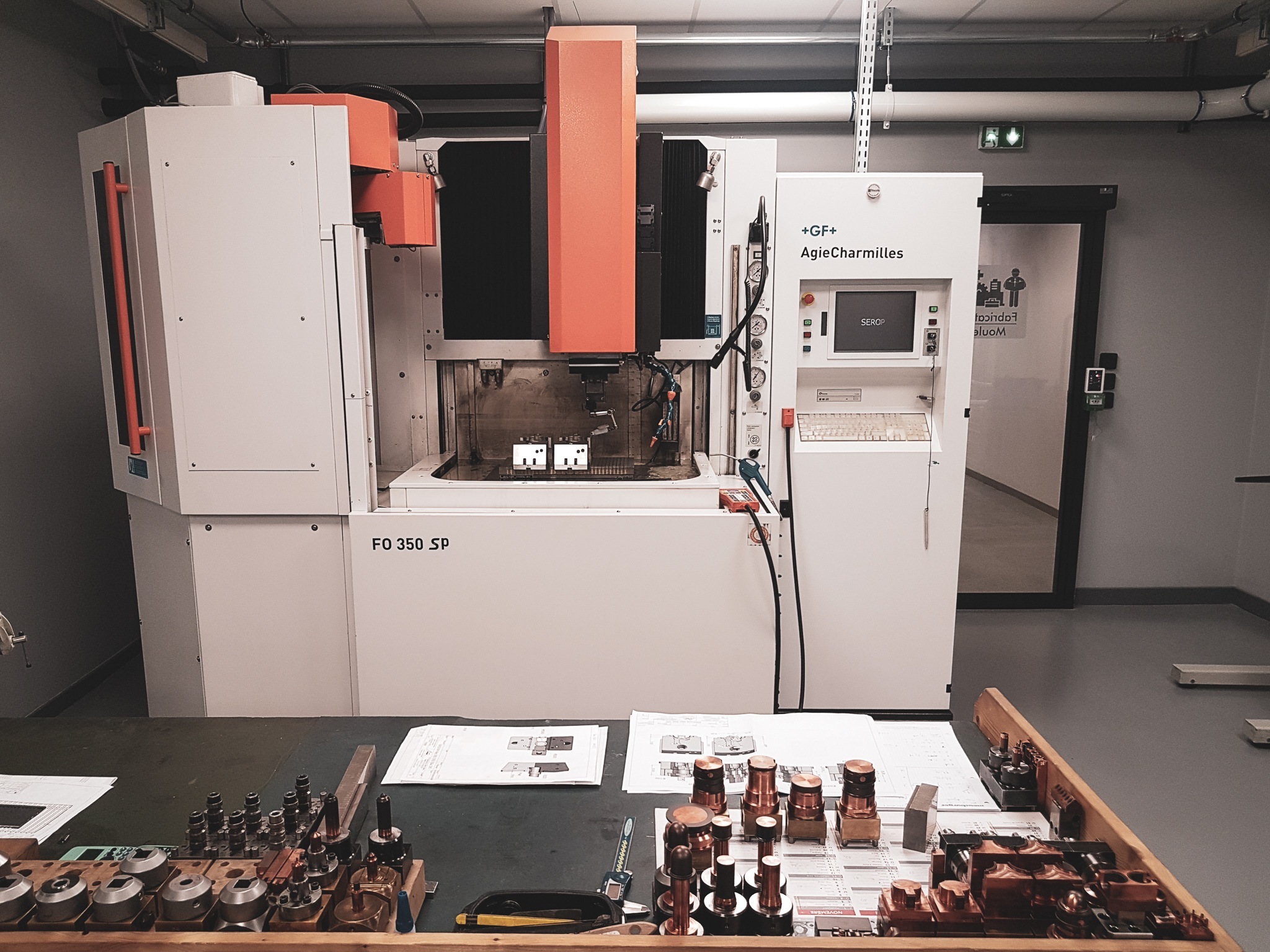

SEROP produces multi-cavity plastic injection molds. The cavities are made by 3D laser printing process to optimize coolant channels and thus the heat exchanges and reduce the tool development time. Flow studies are conducted, using MoldFlow software.

SEROP

Multi-cavity plastic injection molds

SEROP produces multi-cavity plastic injection molds. The cavities are made by 3D laser printing process to optimize coolant channels and thus the heat exchanges and reduce the tool development time. Flow studies are conducted, using MoldFlow software.

Services

Designing and building tools as well as optimizing tools

Definition of injection parameters

Metrology and compliance

Production of pilot series for industrialization services by using 3D plastic printing HP machine

Commercial contact

Bruno Bottollier

Email : bbottollier@savoy-serop.com

Phone : +33 7 86 89 29 22

Services

Designing and building tools as well as optimizing tools

Definition of injection parameters

Metrology and compliance

Production of pilot series for industrialization services by using 3D plastic printing HP machine

Commercial contact

Bruno Bottollier

Email : bbottollier@savoy-serop.com

Phone : +33 7 86 89 29 22

SAVOY SEROP / Study and realization of molds

A question about a product or service? Arrange a meeting ? Need a quote?

Our support team look forward to assisting you